These 4 things make mild steel rust quickly

Current developments in construction technology allow people to use various building materials to build a house, one of which is using light steel for the roof of the house. Even though it is included in the category of lightweight roof trusses, this type of roof truss turns out to have quite good durability, is not easily damaged and is rust-proof. Even though it is coated with an anti-rust substance, this does not mean that this mild steel is free from corrosion or rusting. There are at least four things that can trigger rust on mild steel.

1. Scratched by work tools

Avoid scratching light steel with work tools. The scratch will remove the protective anti-rust layer on the mild steel. The oxidation process between oxygen and chemicals in steel is what will cause rust. When damage occurs due to open joints or wrong cuts, it is best to quickly re-coat the light steel using anti-rust paint.

2. Acid solution

This acid solution, which is generally found in cleaning solutions and paint removers, can easily remove the anti-rust coating on mild steel. Acidic liquids or solutions are very reactive when they come into contact with the surface of mild steel. If that happens, the coating or anti-rust layer on the mild steel will peel off and immediately cause rust.

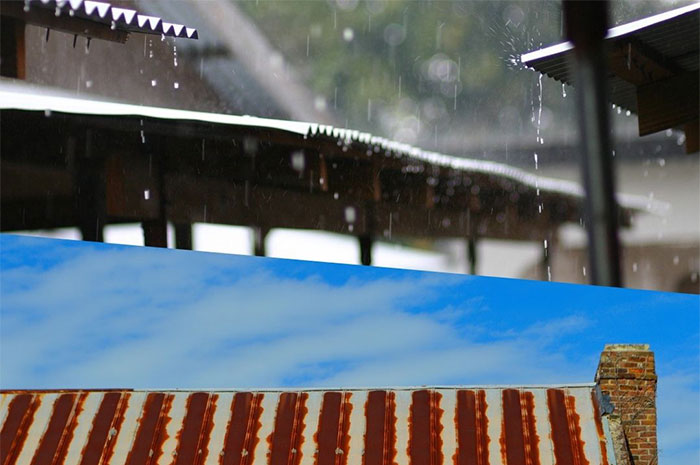

3. Rain and heat

Basically, light steel is not an exterior material and is not created to withstand massive exposure to rain and heat. Exposure to weather such as rain and heat on a large scale and continuously can erode its anti-rust layer. If you have purchased light steel but will not use it in the near future, it is best to store it indoors where it is protected from exposure to the weather. As a precautionary measure, light steel should be placed in a closed room protected from sunlight and rain and do not install light steel during the rainy season.

4. Cement water

Water mixed with cement that sticks to the surface of mild steel will harden over time and cause a chemical reaction that has the potential to damage the anti-rust layer on the mild steel. This will quickly happen on the surface of mild steel whose anti-rust layer is zinc (galvanized). During the construction phase, what must be done is to protect the light steel from the concreting or cement mortar process. Also avoid applying cement mixture for carpus or roof tiles directly on the light steel frame and create a waterproof layer as a barrier for this.